- Width: 52,5 mm

- Classification: For DC charging stations

- Response value: 1 - 500 kΩ

- IMD type: AC, DC, AC/DC

- Nominal voltage IT system: AC 0 - 230, AC 0 - 690 (Coupling device), DC 0 - 230, DC 0 - 1000 (Coupling device) V

- Auxiliary voltage: AC/DC

- Bus interface: Modbus RTU

Highlights

- Especially suitable for DC charging stations according to the IEC/EN 61851-23 standard

- Higher productivity through early fault detection

- Preventive maintenance

- Increased fire safety through early detection of insulation faults

- Simple device setting via rotary switch

- Width: 52,5 mm

- Classification: For DC charging stations

- Response value: 1 - 500 kΩ

- IMD type: AC, DC, AC/DC

- Nominal voltage IT system: AC 0 - 230, AC 0 - 690 (Coupling device), DC 0 - 230, DC 0 - 1000 (Coupling device) V

- Auxiliary voltage: AC/DC

- Bus interface: Modbus RTU

Insulation monitoring at DC charging stations

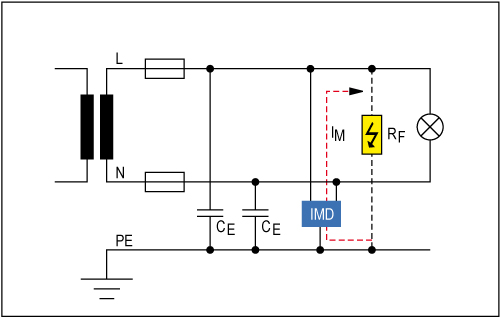

The number of electric vehicles is steadily increasing and will grow even faster in the future. Thus, the expansion of the charging station infrastructure is also being driven forward, because DC charging stations are the first choice when electric vehicles are to be charged within a very short time. During the charging process, it is essential to ensure electrical safety. For this purpose, an unearthed DC power supply system (IT system) with insulation monitoring is set up and monitored by means of an insulation monitoring device (IMD). The user must not be exposed to danger from high voltages (up to 1000 V) at any time. The insulation monitors RN 5897/020 are used especially for DC charging stations according to the IEC/EN 61851-23 standard and take over the monitoring during the charging process from the charging station into the vehicle.

Insulation monitoring of switched off consumers

Electrical systems must be monitored. There are several reasons for this: This protects people and plants from damage, and monitoring also makes a significant contribution to availability. Modern insulation monitors can even monitor drive technology components when they are not in operation.

Electrical drive technology plays an important role in many applications in mechanical and plant engineering. If a drive fails once, this inevitably leads to a standstill of the machine or system. In the worst case, complete plants can no longer produce, which is usually associated with high costs.

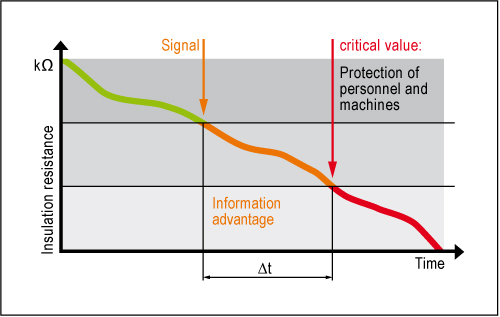

Early information prevents system downtimes

Insulation monitors of the VARIMETER IMD series monitor the insulation resistance in unearthed systems (IT systems). The DIN VDE 0100-410 and DIN VDE 0100-710 standards prescribe the use of an insulation monitor in unearthed systems to report an initial fault between an active conductor and a body or against earth. The insulation monitoring device must trigger a visual and / or acoustic signal when the first fault occurs. Malfunctions as a result of insulation faults and the associated cost-intensive interruptions to operation, personal injury and damage to property are avoided. The insulation monitor was developed especially for use in modern power supplies, which often also contain converters, power converters, thyristor controllers or directly connected DC components. EMC interference suppression measures with their leakage capacitances to ground play a major role there.

In unearthed power supplies (IT systems), no active conductor is directly connected to ground. In the event of an insulation fault, therefore, only a small fault current can flow, caused mainly by the system leakage capacitance. Overcurrent protection devices do not respond here and the voltage supply is maintained. The work process, e.g. an operation, can be completed. The permanent monitoring of the insulation resistance by the isowatch ensures early information about possible hazards. Faults can be eliminated in good time.

The insulation monitor is connected between the active system conductors and earth. With active measuring methods, it superimposes a measuring voltage on the network. If there is an insulation fault, the measuring circuit closes and a small current proportional to the insulation fault flows. This measuring current is evaluated by the electronics of the device. If the insulation resistance falls below a certain value (response value), a message is issued by the device. Insulation monitoring devices of the VARIMETER IMD family are available for direct voltage (DC), alternating voltage (AC) and mixed networks (AC/DC), e.g. networks with voltage or frequency changes, high system leakage capacitances or DC voltage components.

You want to monitor grounded power supplies (TN and TT systems)?

Residual current monitors are used for insulation monitoring in grounded systems. Residual current monitors (RCMs) measure and monitor residual currents in grounded systems (TN and TT systems). They are used in systems where, in the event of a fault, a signal is to be given but no shutdown is to take place. Faults as a result of insulation faults thus do not lead to unwanted interruptions in operation, damage to property and high costs.

Optimally adapt insulation monitoring devices to your industry

Insulation monitoring in medical technology as well as in data centers and IT. Making ships, ports and gantry cranes electrically safe with Dold insulation monitors. High system availability also for renewable energies (PV systems) as well as airport and traffic lighting. Electrical safety also for mobile power generators, eMobility and DC charging stations.

Downloads

- Product overview VARIMETER (PDF - 1.24 MB)

- Flyer Insulation monitor RN 5897/300 (PDF - 204.81 KB)

- Flyer Insulation monitor RN 5897/020 (PDF - 273.35 KB)

- Flyer Insulation monitor LK 5896/900 (PDF - 212.22 KB)

- Flyer Insulation Monitor LK 5895 / LK 5896 (PDF - 278.53 KB)

- Flyer Insulation Monitor LK 5894 (PDF - 245.49 KB)

- Flyer Insulation monitor RN 5897/010 (PDF - 225.66 KB)