- Width: 52,5 mm

- Adjustable measuring ranges: 0,01 - 3 A

- Operate delay: Yes

- Classification: Type B (AC, DC even and pulsating)

Highlights

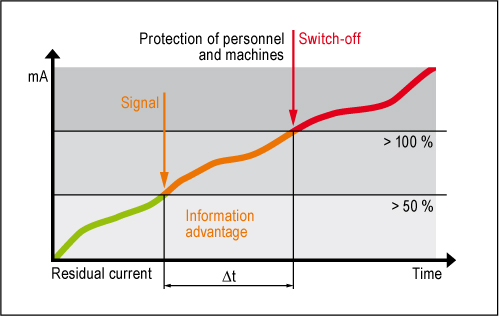

- High plant availability due to early fault indication

- Time and cost-saving maintenance

- Simple adjustment via latching rotary switches

- Wire break detection in the measuring circuit

- Report instead of shut down

Signaling instead of shutting down - Functional principle of residual current monitoring

Unplanned interruptions in the operation of machines and systems are a considerable cost factor. Insulation faults are a frequent reason for this. In grounded systems (TN and TT systems), residual current monitors ensure reliable fault current monitoring. Expensive downtimes are thus avoided, and a possible fire hazard, which is latent due to creeping insulation faults, is also prevented. The residual current monitors can be used universally, as they detect direct (DC) and alternating (AC) currents equally.

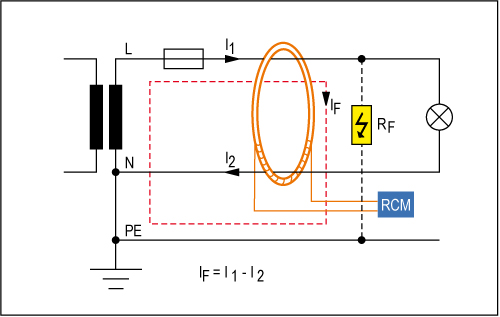

The residual current measurement is carried out via an external residual current transformer. All conductors of the feeder to be protected (without PE) are fed through the transformer. In a fault-free system, the sum of all currents is zero, so that no voltage is induced in the residual current transformer (measuring current transformer). If a residual current flows via earth due to an insulation fault, the current difference in the current transformer causes a current which is detected and evaluated by the residual current monitor.

Difference to residual current circuit breaker:Residual current circuit breakers, so-called RCD (Residual Current Protective Device), always cause an immediate shutdown. The consequences are cost-intensive plant shutdowns or loss of data.

Residual current monitors, on the other hand, can display the current fault current and signal when response values are exceeded and/or also switch off. In this way, the plant operator receives early information about critical operating states that are developing and thus avoids possible personal injury, fire damage and material damage. The residual current monitors of the VARIMETER RCM family, with external or also integrated residual current transformers, permanently monitor your plant for fault currents. Degradation of insulation is indicated at an early stage so that preventive maintenance and servicing measures can be initiated.

All conductors of the feeder to be protected (except for protective earth) are routed through the residual current transformer. In a fault-free system, the sum of all currents is zero; no voltage is induced in the transformer. If a fault current flows via earth, the current difference causes a current in the transformer. This is detected and evaluated by the electronics of the residual current monitor.

The measuring method applies to residual current monitors in applications with pure AC currents AC and pulsating DC currents DC (type A according to IEC/TR 60755). Special measuring procedures are used for AC/DC sensitive residual current monitors (type B). They are suitable for measuring all types of residual currents in electrical installations: AC, pulsating and smooth DC residual currents.

Do you want to monitor unearthed power supplies (IT systems)?

Insulation monitoring devices are used for insulation monitoring in unearthed systems. Insulation monitors, also called IMD (Insulation Monitoring Device), monitor the insulation resistance in unearthed systems (IT systems). The standards DIN VDE 0100-410 and DIN VDE 0100-710 prescribe the use of an insulation monitoring device in unearthed systems to report a first fault between an active conductor and a body or against earth.

Optimally adapt residual current monitoring devices to your industry

The application spectrum of residual current monitors ranges from data centers/IT, building automation, steel and metal industry to hospitals, traffic engineering, paper and printing industry.